Porcelain Insulator News

by Jack H. Tod

Reprinted from "INSULATORS - Crown Jewels of the Wire", December 1974, page 21

Preferably direct porcelain news item and questions directly to Jack H. Tod,

3427 N. 47th Place, Phoenix, Ariz. 85018. All mail will be answered if reply

stamp is enclosed, and the most newsworthy items and questions of general

interest will be published an space permits.

Listed below are the porcelain dry press markings which have accumulated

since the last listing of these in the February 1974 issue. About half of these

are attributions for previously listed markings. The collector reporting the new

ones or attributing others is shown for

each item with the following keying:

-

(1) Mike Barbieri

- (2) Walter Lehnert

- (3) Carl Lencse

- (4) Fred Richardson

| AJAX |

Ajax Elec Spclty Co, St. Louis, radio (2) |

|

Amer Porc Co. E. Liverpool,

O., std pore (3) |

| B. E. CO. |

Bryant Elec Co, Bridgeport, Conn., spcl (3) |

| BEAVER |

Beaver Mach & Tool Co, Newark, spclty (2) |

| C. C. E. |

unattributed, #334 wiring cleats (9) |

| CORWICO |

Cornish Wire Co. New York, radio

insuls.(2) |

| D & S P Co. |

Davidson & Stevenson Porcelain Co.,

East Liverpool, Ohio,

standard porcelain (3) |

| D & S |

ditto (3) |

| EAGLE |

Eagle Elecl Mfg Co, L.I. City, NY, radio (2) |

| GUARDIAN |

The Muter Co., Chicago, radio ant. insul (2) |

| HARDWICK HINDLE INC. |

of Newark, N.J., spclty item (2) |

| HECO |

Heineman Elec Co, Phila , radio ant. (1) |

| Isolantite Mfg Co. |

of Stirling, N.J., radio & spcl (9) |

| J.H,P. & S. |

J. H. Parker & Son, Parkersburg, W. Va. (3) |

| ROCK |

unattributed, #334 wiring cleats (2) |

| R R |

Radio Receptor Co, NY City, radio item

(2) |

| SENSORY |

Heineman Elec Co, Phila., radio ant. (1) |

| The Solderall Co. |

of Newark, N.J., radio ant.

insuls. (2) |

| T.T.P. Co. |

The Trenle Pore Co, E

Liverp'l, std pore. (3) |

|

Monogram-WS, unattributed,

#334 cleats (3) |

|

unattributed, early wiring cleats (4) |

|

unattributed, early wiring cleats (4) |

|

Arrow Elec Co, Hartford,

Conn, spelty (3) |

THOSE MLOD PITTSBURG INSULATORS

Pittsburg High Voltage Insulator Co., Derry, Pa. was established in 1908 and

was ultimately wholly owned by Westinghouse by 1922. They cataloged a very large

number of pin type styles, more than any other company, and tended to go after

the "short order" business other companies didn't really care for.

Pittsburg not only made many types of special designs for customers and applied

customer markings on many different items, but they also made foreign styles for

export overseas and quite a variety of beehive and other styles for Canadian

railroad companies.

One other thing sets Pittsburg apart from all the other U.S. insulator

manufacturers, and that is the fact that many of their styles, all wet process

items, were made in two-part forming press molds. On these items, a Mold Line

Over Dome is continuous from one base rim all the way up over the insulator and

down to the other side of the base.

This manufacturing method allowed them to make unusual shapes such as the

"eared" types U-393 and U-395 by the wet process, and a byproduct of

the method was that any side grooves could be included in the parting-type mold

and did not have to be cut in after pressing by "green trimming"

operations.

Evidently Pittsburg got carried away with this idea of eliminating the extra

trimming operation, and they made many very ordinary styles by this method. I

have noted at one time or another all the following Pittsburg styles with MLOD:

U-5, 42B, 42C, 68, 73, 81, 84, 106, 110, 117, 149A, 154, 202A, 224, 230, 243,

265, 359, 361, 377, 393, 393A, 395, 410, 438A, 499, 529, 540 and U-570.

Some of these Pittsburg MLOD insulators I have seen which were from actual

use on lines showed flaws associated with the mold line, and the Pittsburg

dumpage was full of many insulators which cracked at the mold line during

firing. Being ever more curious about the whys and wherefores of Pittsburg's

methods in view of the basic fault in this manufacturing process, I some time

ago quarried John Stout, plant manager of McGraw-Edison's insulator plant at

Macomb, Ill. His reply, in part was:

"... I think you are right in the idea that this was a method ... to get

special shapes as long as there are no undercuts in one operation. I have made

insulators by the dry process by this procedure and some experience in pressing

wet process clay by the same technique.

"As you know, ceramic materials from which insulators are made are not

spherical particles but a combination of plates and particles in which one axis

is longer than the other. During a forge type pressing of a plastic body these

particles are highly oriented at the parting line where the excess clay escapes

and the dies come together. A differential shrinkage occurs at the parting line

resulting in cracks and a plane of weakness relative to electrical and

mechanical strength. Just trimming of the flush line is not sufficient to remove

this weakness. We find that in pressing plastic clay the parting line of the two

dies must be moved to one end or a side and not part within the body surface of

an insulator. It is for this reason the type operation to which you describe has

never been popular."

This peculiar characteristic of most Pittsburg insulators, together with

several other factors, allows us to readily attribute virtually every Pittsburg

specimen to that company, although only one specimen is known which is actually

marked "Pittsburg" (reported in this column in October 1973)!

Any wet process pin type with this complete two-part mold line is a

Pittsburg, but be careful in that some dry process types with mold lines (never

made by Pittsburg) are so well made as to deceptively approach wet process

quality and appearance. The mold line on the Pittsburg is always carved off with

a wishbone tool or otherwise fettled down flush with the surface, and it may

even be indistinguishable on specimens with a heavy, dark glaze.

As another attribution aid, Pittsburg cataloged many of their peculiar

styles, and these are noted in my book in the checklist of confirmed

manufacturers of the 900+ styles in the Universal Style Chart. Furthermore, dump

digging at Derry has confirmed Pittsburg manufacture of many styles made by no

other company.

Yet another method is that we have verified by plant dumpage and other

factors that all the date code items (such as May 17 P.M.) were made by

Pittsburg, plus all the full date (June 23, 1915) items in the 1911-1915 era,

plus all item with the following customer markings: SOO, P.R.R., POSTAL,

N.A.T.Co. and the U-241A specimens marked JOHNS-MANVILLE.

And there is one real clincher which gives away all Pittsburg pin types, and

most collectors are aware of this. The top of the pin hole is always either (1)

perfectly flat or (2) some combination of concentric circles, a typical one

being as illustrated at the right. I've looked up in the pin holes of literally

thousands of insulators of all manufacturers and have never found any which have

this Pittsburg feature -- excluding dry process types, of course, some of which do

have flat topped pin holes.

Experienced collectors can also tell a Pittsburg insulator nine times out of

ten just by its glaze. They always had a very richly colored glaze including

walnut browns, reddish-mahogany, beautiful carmels banded with darker browns and

an unmistakable bright baby blue. To date I have never seen a Pittsburg in

cobalt blue, green, gray or yellow.

Yes, Pittsburg was different from the other companies in many ways, and some

collectors choose to specialize in Pittsburg for that reason -- even though

virtually all of their pet specimens are unmarked.

Dear Jack:

I am sending to you a couple of little insulators I found in a dump on an old

ranch near Hardin, Montana.

I have never seen anything like these so was interested, of course. Any

information you might have would be appreciated. Enjoy your articles in C.J.

John L. Schall

Santa Paula, Cal.

- - - - - - - - -

Dear John:

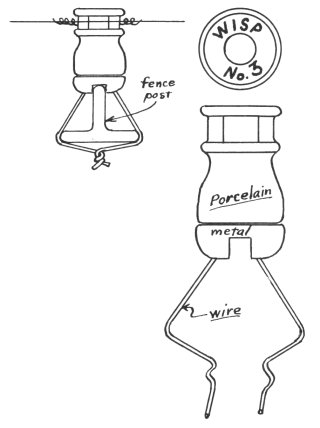

These are special electric fence insulator knobs made by Wisconsin Porcelain

Co., Sun Prairie, Wis. They used markings WP, WIS-P and a tradename WISP as on

these items. The No. 3 is their catalog number for this.

This one is meant for use on standard steel posts as I've shown in the sketch

above left. Thus, the wire pigtails to secure it to the post.

You will note on page 163 of Gerald Brown's second edition of

"Collectible Porcelain Insulators" an identical WISP porcelain item

but with a bottom insert having a nail assembly instead of the wire pigtail, and

that one was for use on wooden posts. These bottom attachments screw up into the

bottom cavity of the porcelain on actual threads, and this is the only knob

having this feature. This is a specialty item, and the No. 3 has no relation to

the standard porcelain knob numbering system.

Jack

Dear Jack:

I have a U-31 pony with an embossed marking on its dome I've never seen

before, and do you know anything about it? (P . P . INC.)

I have an unmarked Lapp U-634B with a very clear Kiln loader control number

(K 5) between the ears. I found these with others without the marking. Do you

know if these were used one per lot or what?

I also just got a couple of U-70 (thru-hole in dome), and have you been able

to find out what this is for yet?

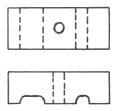

A few months ago when I went down into the basement, I happened to look up at

the ceiling, and I found a couple of wooden cleats (shown here full size)! Don't

get excited, as these were holding the wires from the outside phone tap. Also,

my house is only ten years old! I wonder how many of these the telephone company

used, and how many other wooden cleats have been produced.

Mathew Grayson

Roslyn, N.Y.

- - - - - - - - -

Dear Mathew:

It's simple. I just goofed by forgetting to put those P.P. Inc. dry press pin

type markings in the book. There are several varieties and combinations of

these, two of which are shown above. The U-31 pony is their #6109, and the U- 56

exchange is their catalog #6119. The small marking at left above is straight

across the crown top, and versions of the other one are circular around the

crown top.

From Lapps I have seen at utilities and in collector batches, I'd say they

used the K numbers on only a portion of each lot, maybe just several on each

kiln car shelf just for later identification after firing.

No ideas yet why the holes in types like U-70. An O-B employee last year gave

we his recollections on it, but it sounded so implausible that I chose to ignore

it. If someone back east could somehow manage to go through the right files at

the SCEL building at Ft. Monmouth, he would find the answer to this and many of

our questions on other Signal Corps insulators. Letters there reach buck

passers!

Yes, theme wooden phone tap cleats are modern, if not still current. I

believe their origin was Signal Corps, as are also quite a variety of wooden

knobs with designations in army stores catalogs as "trench knobs".

Jack

Several times in the past we have mentioned the large number of independent

users of all insulator types, and that what collectors see in all their travels

is such an extremely small percentage of usage in all other areas. Styles which

are very uncommon in collector hands or which may still be unreported types

could well be standard items with dozens of users where we just haven't been.

Reproduced below is a summary of the utilities listed and described in the

81st Edition of the "Electrical World Directory of Electric Utilities"

1973, McGraw-Hill, Inc.

Also keep in mind that many of these utilities bought up many of the earlier

ones or are the result of merged companies. And don't forget to add the

countless trolley companies, railroads, mines, factories and telephone companies

that all used porcelain insulators in great variety and quantity.

| UNITED STATES |

|

| 12 |

Non-Operating Holding Companies |

| 25 |

Wholesale Generating

Companies |

| 11 |

Service Companies |

| 11 |

Divisions |

| 274 |

Investor-Owned Companies |

| 1,769 |

Municipal Systems |

| 923 |

Rural Electric Cooperatives |

| 58 |

Public Power Districts |

| 7 |

Irrigation Districts |

| 40 |

U.S. Government |

| 9 |

State-Owned Systems |

| 1 |

County Systems |

| 2 |

Mutual Systems |

| 3 |

Transmissions |

|

|

| U. S. POSSESSIONS |

|

| 2 |

Government Authority |

| CANADA |

|

| 2 |

Holding Companies |

| 5 |

Wholesale Generating Companies |

| 1 |

Service

Companies |

| 13 |

Investor-Owned Companies |

| 410 |

Municipal Systems |

| 9 |

Provincial Power

Systems |

Dear Jack:

Regarding the radio lightning arrestor which you could not fully Identify

(see November Porcelain News), this is undoubtedly the MUTER CO., Chicago, and

this company was In the radio parts business back in the 1930's.

... I recently got a whole bunch of new wiring cleats (#334 types) including

DAVIDSON, A.S.P.Co., P.P. INC. in case you know of any buddies who want to swap

on these.

Walt Lehnert,

Minneapolis

Janet Sievert (Cupertino, Col.) sent photo of a pretty pin type similar to

U-642 and which has a very clear marking as shown here. This is a new one for

Canadian Porcelain Co. and, like the one shown on page 10 of the May 1974 issue

of Crown Jewels, the C in the marking is essentially completely closed. Note

the fancy serifs on the letters.

This in C.P. Co.'s catalog #408 with the smaller grooves and #845 with bigger

grooves -- both having a 1-3/8" pin hole. They first cataloged these in

1916. After about 1940, they also made the #845 style with standard 1" pin

hole as their #2300 and with sanded hole as their #6838.

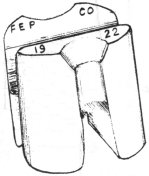

Dear Jack:

This brown porcelain has very deep grooves all around and is marked as shown.

What in it? Made by whom? When? Where? It's a strange one to us, and we'd like

to hear from anyone about this.

Mr. & Mrs. F. S. Summers

Arcata, Cal.

- - - - - - - - -

This in a circuit "break knob" and is used to break circuits at

desired points such as in series street light circuits. This specific design was

originated by Pass & Seymour, Syracuse, N.Y. and is covered by their patent

#476,828 of June 14, 1892 by Albert P. Seymour ("Circuit-breaking

Knob").

Letters patents expire in 17 years, and your specimen was made by Findlay

Electric Porcelain Co., Findlay, Ohio. They were in business 1911 to 1927. The

1922 number on the specimen is their catalog number of this item. They made

these in different glazes, and I have it in dark walnut brown, white and a light

orangy brown.

Jack

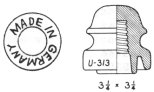

Roy Licari (Washington, D.C.) sent for my inspection a white pin type almost

identical to U-313 and which has a MADE IN GERMANY stamp (full size here) up in

the top of the pin hole.

This item was obviously made for export from Germany and possibly to this

hemisphere because of the 1" standard pin hole and being a direct copy of a

U.S. style

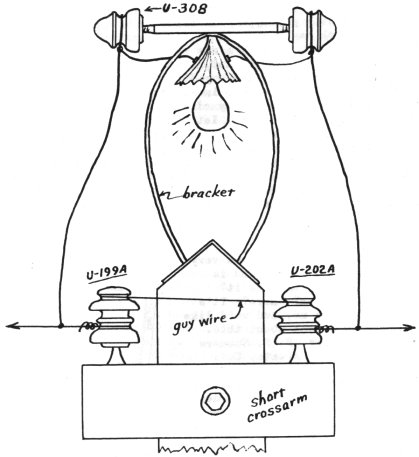

Dear Jack:

Frank Donnelly's letter in the October issue reminded me that I have long

been meaning to write about a non- telephone application for porcelain

transpositions. I'm enclosing a rough sketch, only from memory, of a series arc

light installations once in use at the P.R.R. roundhouse in Ebernezer, N.Y.

Since this yard was abandoned and the wires removed, somebody has taken all the

transpositions.

Note that the tramps in use here were to afford a means for removing

torsional stresses in the crossarms by guying together the tops of the tramps

with the extra groove at their tops. This could also be done with other

multigroove styles such as the Hi-Tops, but these were all installed many years

before the Hi-Tops were designed in the 1930's Dan Rider,

Buffalo, N.Y.

- - - - - - - - -

Dear Dan:

Yes, any mickey mouse scheme which requires four pin type

insulators on a pole top just to hang one arc lamp certainly deserves

recognition!

Jack

|